Production Equipment

In 2022, the company carried out the transformation of high-end sweater knitting intelligent production line, and the project purchase equipment investment of 52.112 million yuan (model: KS3-72SC-I-10.2G) introduced 228 sets of first-line clothing computer flat machines from Switzerland. Add Hui garment industry ERP management software V7.0 professional edition 1 set of nearly 600,000 yuan, used for the design and development of seamless textiles, production and sales, the establishment of intelligent factory.

(Standardized products, cloud deployment, rapid implementation, workshop Kanban to achieve visual management) Intelligent factory Intelligent production management system (ERP+MES) is a set of management system for the workshop executive level of hosiery manufacturing enterprises. It mainly provides enterprises with management modules including manufacturing data management, planning and scheduling management, production scheduling management, inventory management, quality management, procurement management, cost management, production process control, bottom data integration analysis, upper data integration and decomposition, and creates a solid, reliable, comprehensive and feasible manufacturing collaborative management platform for enterprises.

Using the industry-leading Tange system, the use of bottom plate, auxiliary roller with flexible pulling device, to achieve a line of clothing, eliminate the sleeve, stitching and other complex processes, while better meet the fabric shoveling needle, closing needle, needle placement local knitting needs, improve production efficiency, reduce operating costs, improve product quality and wearer comfort.

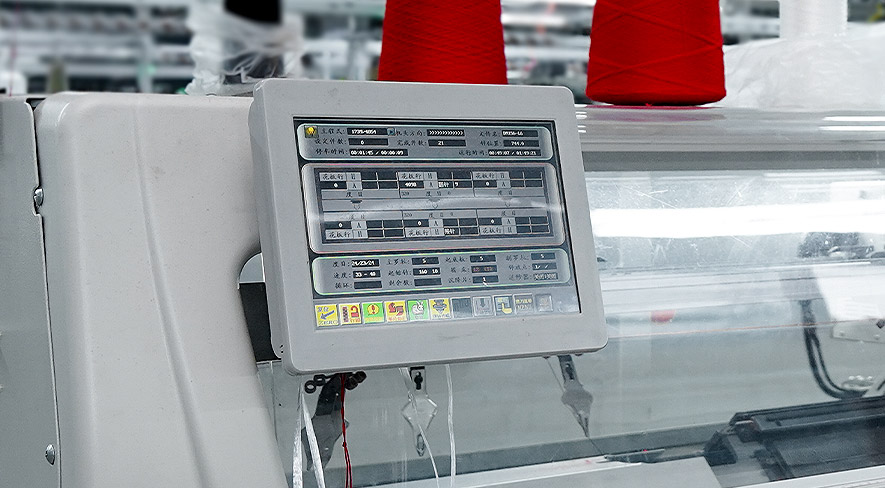

Color display graphical interface, through the screen page can view the triangle's working status and actual position and the number of woven pieces of the state, and in the machine running at any time to adjust the degree of eye, speed, tension and other working parameters, to maximize the convenience of operation and save time.

Through the use of ERP and MES systems, the whole process tracking of production orders in the processing process, quality traceability, digital production management of the whole process, and real-time data of order production can be shared with customers who place orders.

The first-line molding technology is a whole piece, three-dimensional way, one-time weaving out, without cutting, sewing and other post-process, equipment networking actively report the production data.

Production management after the use of ERP system and MES system, the entire production process to achieve planned production, intelligent supply of logistics inside the factory, information flow according to the production schedule automatically pushed to the relevant posts, so as to achieve seamless integration of logistics, information flow, process information.

Through the transformation of the above A and B, it can improve the man-machine collaboration efficiency and the integration level of enterprise information, improve the interconnection and integration ability of ERP, MES, APS and machine equipment network, and realize the comprehensive digitization of human, machine, material and other elements in the production process.

The implementation of intelligent factories and intelligent manufacturing has brought "two upgrades and three reductions" to enterprises.

Through intelligent transformation, enterprises can greatly reduce the production cost of enterprises, because the first-line molding of clothes, the high degree of intelligence of equipment, fewer processes can greatly improve the delivery time of orders, and can better undertake the small batch and multiple batches of fast return orders on the market.

Seize the opportunity to accelerate the development of strategic emerging industries, based on the existing industrial base, and vigorously develop high-tech fibers and their composite materials.

The project relies on the Internet platform to carry out intelligent transformation, give full play to the industrial base advantages formed by the agglomeration of existing enterprises, and through the construction of chain, supplement chain,

The construction of the project can maximize the radiation driving role of the enterprise, promote the economic development of the surrounding towns, and improve the living standards of the people of Haiyang.

The construction of the project can make new progress in social harmony, the Chinese dream and socialist core values more deeply rooted in the hearts of the people, and the quality of the citizens

Shandong Province Yantai city Haiyang city industrial park Qing hong garment

鲁公网安备 37068702000277号

鲁公网安备 37068702000277号